PELAMIS AUSTRALIA PTY LTD

CONTACT US

Adelaide

South Australia 5000

paus@pelamisgroup.com

ABOUT US

Our Story

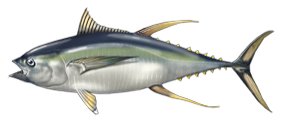

TUNA LONG-LINE CATCH

BROADBILL SWORDFISH

BROADBILL SWORDFISH

TUNA CATCH

Pelamis Long-line fishing vessels are large ultra-modern ships, equipped as specialist “Sashimi” vessels, capable of catching, processing, freezing and storing fish for the highly lucrative Japanese market.

Pelamis tuna is produced under the highest possible standards. Specifically, the fish are treated with respec; they are stunned before being lifted aboard, humanely killed and processed within strict time perameters. The tuna barrels are handled with care, and all best endeavours are taken to reduce bruising and damage to the flesh. The freezing process ensures that each fish is maintained at peak freshness and quality.

They target the high grade tuna species of Southern Bluefin Tuna (Thunnus maccoyii), Yellowfin tuna (Thunnus albacares), Bigeye tuna (T. obesus).

Although not targeted, the western tuna grounds produce by-catch of Broadbill SWwordfish (Xiphias gladius)

TUNA LONG-LINING

The Fishing method is by the use of Pelagic longlines, set and retrieved daily. Longline fishing is considerably more ecologically sustainable than some other commercially significant harvesting methods. The lines cover a large area, and catch only a small percentage of the targeted fish, with the fish coming to the boat "alive and vigorous".

Fish caught are brought to the side of the vessel, stunned by an electric current, and then lifted/pulled on board the vessel through the open door on the main deck. The fish are then quickly and humanely killed, before being gutted, and have the gill plate and tail fins removed. The process bleeds the fish and removes the nerve line, which is then thoroughly washed with sea water, before being transferred to the internal work room, where the individual fish are loaded to the blast freezer.

QUALITY AND FRESHNESS

Fish quality is time critical; which requires that the entire process of preparing the fish for the freezer must be completed within a maximum time period of fifteen minutes of the fish coming on board. Every care is taken in the handling and processing, to prevent bruising or damage to the flesh prior to freezing.

The smaller fresh fish are loaded to freezer trays in the Blast Freezer, while larger fish are suspended from rails and loaded to a different blast freezer. They are then frozen at minus sixty-five degrees Celsius (-65’C) for a minimum period of forty eight hours. This freezing temperature and time duration ensures maximum quality of the fish, and guarantees reduction of the fish core temperature to -60’C.

Having remained in the Blast Freezer for the required time period, the frozen fish is then removed to the work room. A hole is drilled through the tail section, through which is passed a length of nylon line that is knotted in a loop to form a lifting lug, and an identification tag is attached. The frozen fish is then dipped into a freshwater bath, which adds a protective ice blanket around the fish, that adds another layer of protection and preservation to the fish, before being transferred to the lower main holding freezer. Where it is stored at a constant temperature of minus sixty degrees Celsius (-60’C) for the duration of the voyage, or until the product is discharged.

("Click" on menue item to view details)

("Click" on menue item to view details)

("Click" on menue item to view details)

("Click" on menue item to view details)