LONG-LINE FISHING

LONG-LINE OPERATION

The Long-line method is by the use of Pelagic longlines, that are set and retrieved daily using on average 150 kilo-meter of line and 3,500-hooks per set.

The Long-line system is a sophisticated piece of equipment. It is simple in operation, in that the Main Line is hauled or pulled from a guide near the front of the vessel, to travel aft through a series of guides and channels, to be layered into large storage bins at the rear of the vessel. When set, the Main Line is drawn out of the storage bins through a series of guides, to pass over the stern of the vessel. The sophistication of the system is in the machinery that makes this happen.

LONG-LINE OPERATION CONT...

When setting or laying out the main line from the stern of the vessel, as it moves ahead at a constant speed of around seven knots (10 mph). The start of the line is marked by a floating marker buoy, that is equipped with a radio transmitter to mark its position. The branch lines, are attached to the main line at regular intervals by a stainless steel clip, that locks the branch line to the main line. The branch line is then drawn out with the main line until it reaches the baited hook, which is “shot” out to the side of the main line by a hook shooter located at the stern of the vessel.

The distance between the branch lines, and the length of the individual branches varies, and is determined by the Captain or Fishing Master, according to the sea conditions and the species of tuna being targeted. For example, Yellowfin Tuna are found in the surface water table to 150-metres, while Bigeye Tuna are found in the deeper water tables to 300-metres.

The set line is allowed to 'soak' for between five to twelve hours, and is then retrieved to the vessel starting at the end that was last set. The main line is retrieved over the bow of the vessel and passed to the stern main line bin via a series of winches, pulleys and guidance channels or pipes. The individual branch lines are disconnected from the main line and retrieved separately, with any fish hooked landed to the main deck for processing.

PROCESSING THE CATCH

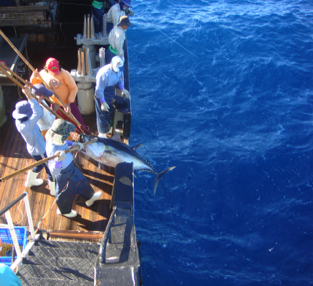

When fish caught on the branch lines come to the side of the vessel they are 'gaffed' using long poles, and then lifted/pulled on board the vessel through the open door on the main deck. The fish are then killed, before being gutted, and have the gill plate and tail fins removed. The process bleeds the fish, which is then thoroughly washed with sea water, before being transferred to the internal work room, where the individual fish are loaded to the blast freezer.

Fish quality is time critical; which requires that the entire process of preparing the fish for the freezer must be completed within a maximum time period of fifteen minutes of the fish hitting the main deck.

CATCH FREEZING

After the fresh fish are loaded to the freezer trays in the Blast Freezer, they are frozen at minus sixty-five degrees Celsius (-65’C) for a minimum period of forty eight hours. This freezing temperature and time duration ensures maximum quality of the fish, and guarantees reduction of the fish core temperature to -60’C.

Having remained in the Blast Freezer for the required time period, the frozen fish is then removed to the work room. A hole is drilled through the tail section, through which is passed a length of nylon line that is knotted in a loop to form a lifting lug, and an identification tag is attached. The frozen fish is then dipped into a freshwater bath, which adds a protective ice blanket around the fish, that adds another layer of protection and preservation to the fish, before being transferred to the lower main holding freezer. Where it is stored at a constant temperature of minus sixty degrees Celsius (-60’C) for the duration of the voyage, or until the product is discharged.

CATCH RECORDS AND GOVERNMENT REQUIREMENTS

Australian Fisheries Management Authority (AFMA) closely monitor all aspects of the Australian Tuna industry. The Government Authorities role is to enforce and control the correct quota is caught, bait is not contaminated in any way, and that the processing method meets the strict health and sanitary guidelines of the Australian Government and the countries that are receiving the final products.

The Indian Ocean Tuna Commission (IOTC) is the International body that manages the catch of all Tuna through the Indian Ocean ensuring that quotas allocated to each country will guarantee that wild stock levels are fished at sustainable levels. The IOTC has introduced and enforced Catch Documentation Schemes as an additional compliance measure to ensure that fish caught outside of the quota system cannot be sold.

Catch and Location

Each fishing vessel must report to the Adelaide office daily, its global position, the catch, and number of fishing 'shots' undertaken. In addition to daily reporting, all boats are electronically monitored by AFMA via VMS (Vessel Monitoring System) and onboard video surveillance.

AFMA inspectors randomly spend time on the vessels at sea to confirm that everything is done in accordance with their strict regulations.